The Glue Talk Blog

According to the Thermal Management Market by Material Type (Adhesive, Non-Adhesive), Devices (Conduction, Convection, Advanced, Hybrid), Service (Installation & Calibration, Optimization & Post Sales), End-Use Application - Global Forecast to 2022 report, the thermal management market is expected to grow at a CAGR of 7.91 percent with a total worth of $14.24 Billion USD by 2022.

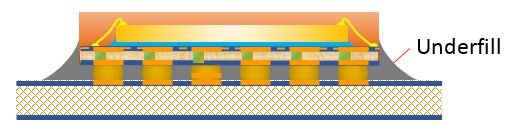

This market growth is likely due to a higher demand for smaller and lighter devices and an increased need for thermal management in consumer electronics. In the thermal cycling of electronic devices, there is relative movement between the Ball Grid Array (BGA) and Chip Scale Packages (CSPs) and the printed circuit boards (PCBs), resulting in mechanical fatigue and failure of the solder joints that electrically interconnect the chip to the board. An underfill, typically an epoxy composition, connects the chip to the board by capillary action and then is heated to cure. The underfill material provides mechanical reinforcement to the solder joints which can increase the life of the chip. This mechanical reinforcement improves dropping performance and raises the thermal cycling performance for CSP, Wafer Level Chip Scale Packages (WLCSP), and Flip Chip components by about seven to 10 times.

The use of underfill is increasing in portable devices due to:

- Finer pitch packages.

- POP packages.

- Thinner main PCBs.

- Challenging drop test requirements.

- Larger BGA/CSPs and WLCSPs.

Device reliability is a critical measure of product performance in the electronics industry. High-performance underfill materials are used underneath chips, devices, or components of electronic products to improve their reliability and offer structural reinforcement of sensitive device components. Our PCB assembly materials have excellent performance and can increase productivity by matching materials to provide consistency in the manufacturing process and device performance.

H.B. Fuller underfills typically offer:

- High reliability (drop, shock, autoclave and temperature cycle).

- Fast flow and easy processing.

- Rework versus reliability balance.

- Excellent flux compatibility.

Read more about our PCB assembly and how we can partner with you to help solve all of your electronics bonding and encapsulation needs.

Blog Categories

Blog Categories

Archive

- 2024

- 2023

-

2022

- February (4)

- March (3)

- April (1)

- May (2)

- June (5)

-

August (6)

- Beverage Labeling Market In Africa: A Huge Potenial

- H.B. Fuller’s Glue House: Scavenger Hunt

- Increasing Global Aging Population: Impacts and Challenges

- Innovations and Key Challenges in Sustainable Disposable Absorbent Hygiene Products

- Supporting Racial Equity in Our Community

- Top 5 Reasons to Invest in H.B. Fuller

- September (4)

- November (2)

- December (2)

-

2021

- January (3)

-

February (7)

- Celebrating Exceptional Service During COVID-19 Complications

- Cyanoacrylates: What They Are and What They Do

- Innovative two-shot bookbinding adhesive

- Make a Difference 2020

- Problem Solving: Paper straws in drinking beverages

- Stronger straws

- Substances of Interest in Disposable Absorbent Hygiene Products

- March (4)

- April (4)

- May (4)

- June (5)

- July (2)

- August (5)

- September (2)

- October (1)

- November (3)

- December (2)

-

2020

- January (4)

- February (2)

- March (3)

- April (4)

- May (3)

-

June (7)

- Community Support in the Era of Coronavirus

- Employee Creates Face Shields with 3D Printer

- Improved Packaging Integrity and Greater Customer Satisfaction

- Liquid-Resistant Paper Straws

- What is a Sealant

- What Is the Future of Commercial Disinfectants

- Winning over consumers with e-commerce packaging solutions

-

July (6)

- Employees Take Action to be Part of Healing and Growth

- Gain a competitive advantage with packaging adhesive solutions

- HB Fuller Company Foundations Commitment to Communities

- Packaging Solutions for the South African Agriculture Market

- Supporting Organizations That Provide STEM Education for Youth

- Where Does Sustainability Stand Amid COVID-19

- August (3)

- September (2)

- October (4)

- November (2)

- December (4)